Redstone Manufacturing: Your Global Metal Manufacturing Partner

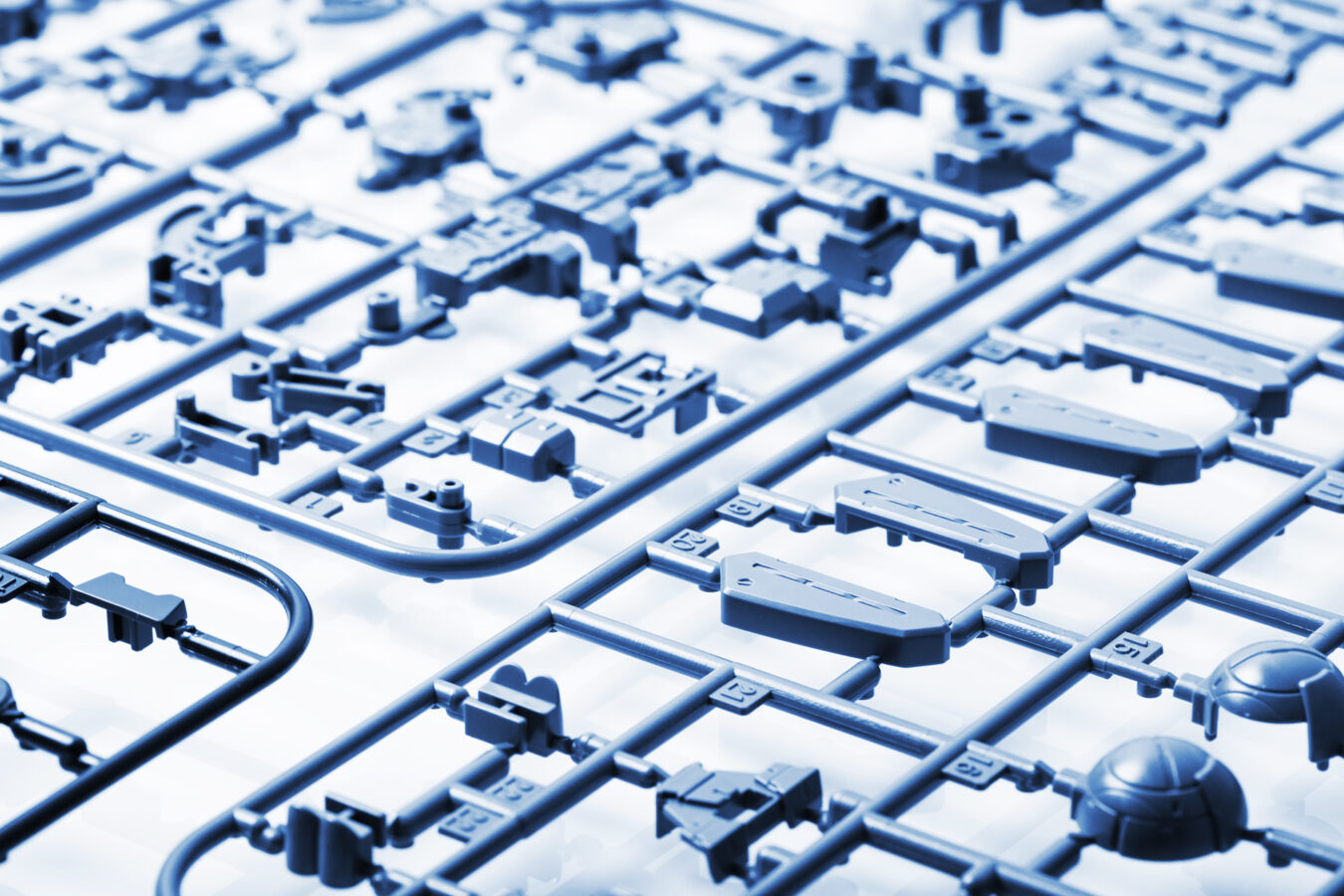

Is there a better way to navigate the complex world of global manufacturing, especially when it comes to metal fabrication? Redstone Manufacturing offers a unique approach, promising a streamlined and reliable path to high-quality metal parts, regardless of your location.

The landscape of international manufacturing, particularly in sectors like die casting, metal injection molding, and CNC machining, can often feel like a labyrinth. Sourcing reliable manufacturers in countries such as China, Mexico, India, Taiwan, and Brazil, presents its own set of challenges. Redstone Manufacturing steps into this arena, aiming to simplify the process. They position themselves not just as a manufacturing facilitator, but as a partner, guiding businesses through the complexities of global supply chains.

Redstone Manufacturing's core mission revolves around providing precision metal parts across diverse sectors. Founded in 2018 in Defiance, Ohio, the company has carved a niche by focusing on quality and reliability. Their approach is rooted in building a network of trusted vendors, with a particular emphasis on ISO 9001 certifications. This focus on quality control and adherence to international standards is a critical factor that separates Redstone from more conventional manufacturing options.

The company's service offerings span a wide range of metal fabrication techniques. They offer die casting, investment casting, and sand casting for consumer products. In addition to this, they offer CNC machining, metal injection molding, plastic injection molding, and sheet metal fabrication services. These capabilities enable them to cater to various industries with diverse product requirements. They are also offering stamping, welding, and other metal fabrication services across five global locations.

Redstone Manufacturing, headquartered in the U.S., strategically positions itself with manufacturing facilities across China, Mexico, India, Taiwan, and Brazil. This global footprint allows them to provide localized support and expertise, while also giving clients access to a wide range of materials and manufacturing processes. Their ability to adapt to client specifications and product needs is a key differentiator.

For those seeking a reliable foundry in China, Redstone Manufacturing presents itself as a compelling alternative. They state that they're not your traditional Chinese foundry, promising to reduce the risks associated with working with foreign foundries. They also provide value-added services designed to impact the bottom line, potentially simplifying the entire manufacturing process.

The company appears to be a bankable supplier, and they are known for delivering quality parts on time, they also have a global manufacturing value chain, providing direct access to various metal alloys.

| Feature | Details |

|---|---|

| Company Name | Redstone Manufacturing |

| Headquarters | United States |

| Founded | 2018 |

| Location | Defiance, Ohio (Headquarters), with manufacturing facilities in China, Mexico, India, Taiwan, and Brazil. |

| Key Services | Die Casting, Investment Casting, Sand Casting, CNC Machining, Metal Injection Molding, Plastic Injection Molding, Sheet Metal Fabrication, Stamping, Welding. |

| Materials | Metal alloys for fully assembled parts and various materials for consumer products |

| Certification | ISO 9001 certified vendors |

| Target Industries | Various sectors, including consumer products |

| Unique Selling Proposition (USP) | Streamlined access to a global network of vetted manufacturers, focusing on quality, reliability, and value-added services. |

| Value Proposition | Quality parts delivered on time, reduced risk of working with foreign foundries, and access to a global network. |

| Contact Information | Sales@redstonemanufacturing.com |

The complexities of materials in the manufacturing process are essential. One of the important factors is the specific alloy of the metal being used. For example, ADC12 is used, which has equivalent materials, including 383 USA/ASTM and ADC12 China GB/T. Also, a Q235 overview, which is a plain carbon structural steel used throughout China, is also an important factor in determining the strength of the product.

It's essential to remember that sourcing and managing metal fabrication can be a complex and sometimes daunting task. The availability of various materials is a crucial factor, as is the global reach of the company. By working with Redstone Manufacturing, businesses can have access to a variety of metal alloys to the fully assembled part, as well as a network of qualified manufacturers.

Redstone Manufacturing also provides access to Q235 steel, a plain carbon structural steel common in China, which includes Q235A, Q235B, Q235C, and Q235D grades. Due to its mild steel characteristics, it is often used without heat treatment, indicating its adaptability for various applications.

The company appears to be a bankable supplier, and they are known for delivering quality parts on time.

In the ever-evolving world of manufacturing, companies such as Redstone Manufacturing are changing the game. With a global network and a focus on quality, they're positioning themselves as more than just suppliersthey're partners in the pursuit of well-made, reliable products.